About Avongard

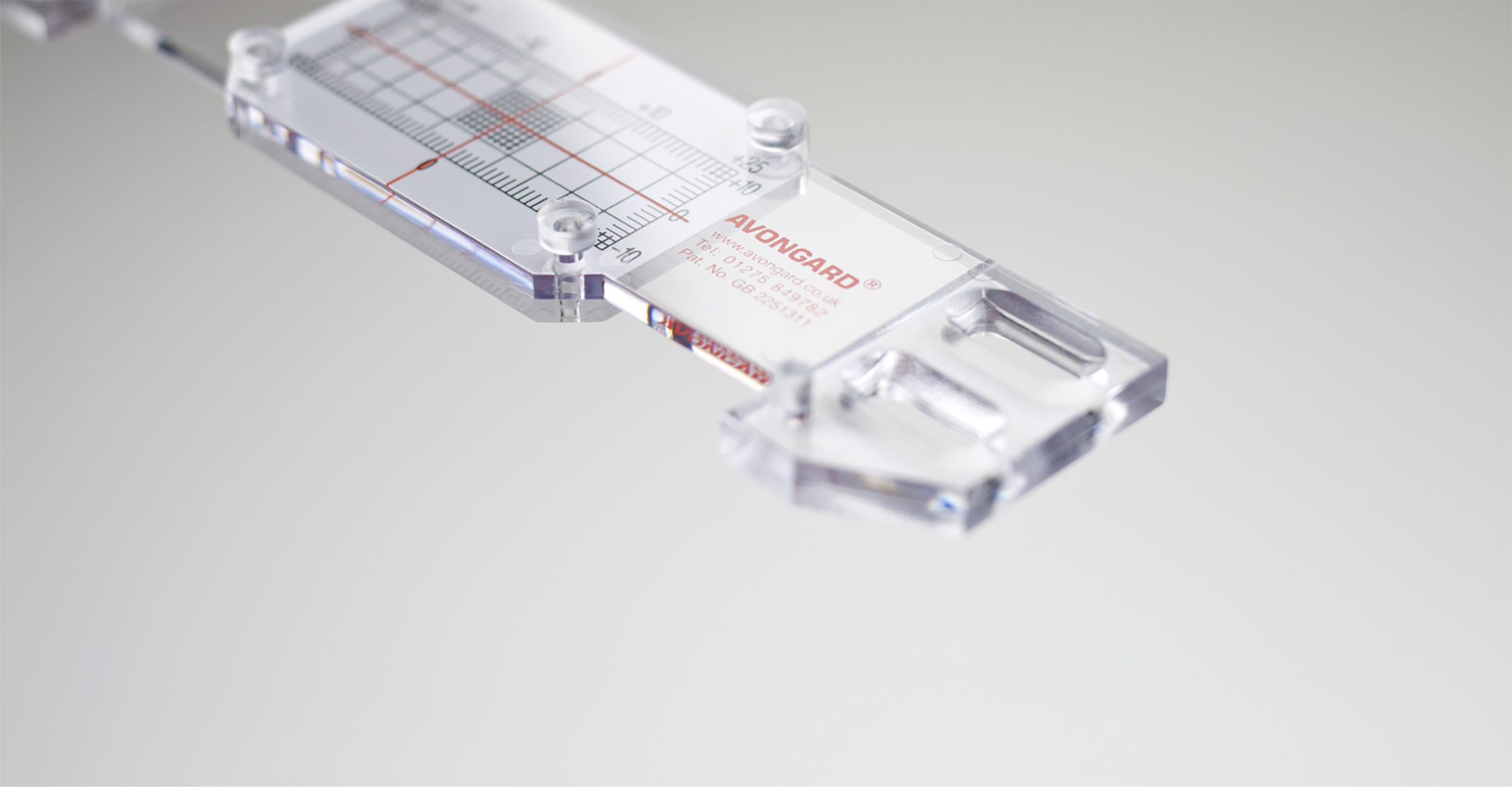

Avongard is a UK company that began trading in 1976 following the invention of the Avongard Standard Tell-Tale by co-founder Roger Johnson – a Chartered Structural and Civil Engineer and Chartered Surveyor. Tell-Tale has since become the generic term for crack gauges, but only Avongard Tell-Tales are the original and genuine product. The Avongard Standard Tell-Tale remains our best-selling product to this day.

Roger invented the Avongard Tell-Tale after recognising a need for a simple but reliable calibrated gauge for the monitoring of cracks. Before the invention of the Avongard Tell-Tale, only crude qualitative methods or high precision high-resolution instruments were available. Now semi-retired, Roger remains active in the business on a consultancy basis, and as our Lead Trainer on our Professional Development Training Courses.

Avongard Tell-Tales are proudly manufactured in Great Britain.

Why do I need to monitor a crack?

Cracks often appear in a building. They may be just hairline cracks and of little significance or they may the first sign of a serious defect.

The crack may not increase in width and therefore would be static. However it may progressively increase in width over time. This progressive movement may suggest there is a serious defect in the foundations and/or the superstructure.

Monitoring and recording progressive changes in the width of the crack over time will confirm or otherwise the nature of the defect and assist with diagnosing the cause.

Why choose Avongard Products?

It is vital the products used for monitoring cracks are quality precision products. Great reliance is placed on the result of the monitoring and the user may be liable if inappropriate remedial work is recommended based on the results of imitation products of inconsistent quality.

Users of Avongard products benefit from the following:

- All the Tell-Tale products including the Crack Width Gauge are manufactured to conform to BS EN ISO 9002:2008 third party accreditation.

- The Tell-Tales and Crack Width Gauge are all manufactured from tough vandal resistant polycarbonate renowned for its durability.

- Every product is supplied complete with a crack monitoring sheet and fixing instructions.

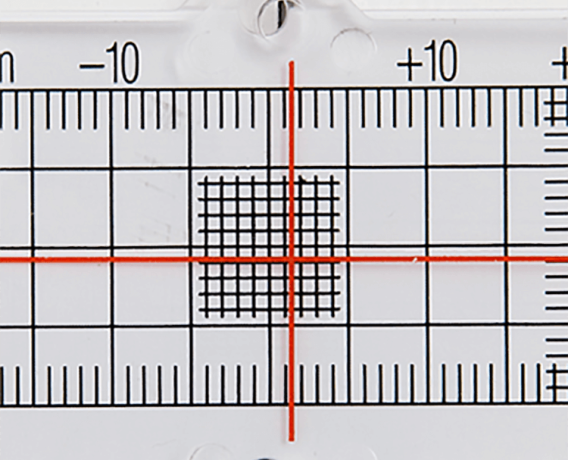

- The usual method of printing numerals and calibrations is to do so using the silkscreen method. However, this method can result in reduced definition. Over time, dimensional inconsistencies can arise too. Avongard products are printed using the silicone pad and etched metal plate method of printing. This results in fine detail definition and good repeatability as well as durability in use. Therefore, the products are easy to read, especially in low light conditions and the user can rely on consistent readings when more than one product is being used.

- The caliper crack monitoring kit is supplied in a full kit complete with accessories. Included in the kit is a manual with advice on obtaining the best results using the caliper system. Only very high quality calipers are supplied. Monitoring to a resolution in the order of 0.1mm demands the highest quality instruments with good repeatability. The calipers accord with EN61326:1997+A1:1998+A2:2001.